Have you ever wondered why your vehicle’s electrical system runs so smoothly? The answer lies in wire insulation. This critical component ensures that the electrical wiring in your vehicle is safe, efficient, and durable.

Wire insulation wraps around the wires and cables in your vehicle, acting as a protective barrier against harsh environmental conditions. In this blog, we’ll explore the importance of wire insulation, detailing its role in vehicle safety, the materials used, and the future of this technology.

Table of Contents

The Role of Wire Insulation in Vehicle Safety

Wire insulation is crucial for vehicle safety. It prevents electrical hazards by protecting the wires from damage, which could otherwise lead to short circuits or even fires. This protection is incredibly important since modern vehicles use more technology, a trend that will continue in the future.

Imagine driving down the road when your vehicle’s electrical system fails—what a nightmare that would be. Proper insulation shields the wiring from heat, moisture, and physical wear, ensuring a safe, reliable electrical system.

Exposed or damaged wires pose a significant risk. Insulation prevents these dangers by providing a robust shield around the electrical wiring. This shielding is vital, as it minimizes the chances of electrical accidents, making your drive safer.

Well-insulated wiring also contributes to the vehicle’s overall efficiency. A vehicle’s electrical system powers everything from the engine control unit to the infotainment system. Quality insulation ensures these systems can operate without interruptions, keeping you and your passengers safe and comfortable.

Wire Insulation Materials

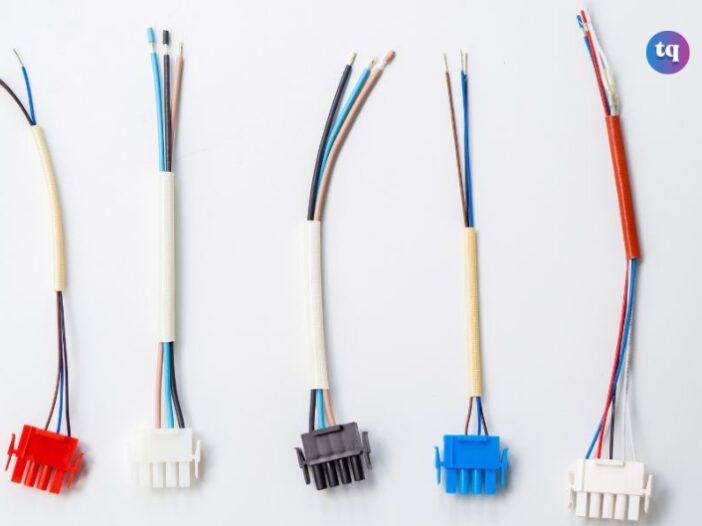

Auto manufacturers use various materials for wire insulation. The most common materials include:

- Polyvinyl chloride (PVC)

- Teflon

- Rubber

PVC is popular due to its affordability and flexibility. It’s excellent for low-temperature applications, making it a go-to for many automotive manufacturers. Teflon is another favorite since it’s great for high-temperature environments. It ensures the electrical wiring remains intact even under extreme conditions. Lastly, rubber offers excellent insulation properties and flexibility, making it suitable for various automotive applications.

Environmental considerations are also important when manufacturers are choosing insulation materials. Many modern manufacturers are exploring sustainable materials that provide the same level of protection while reducing environmental effects.

The Future of Wire Insulation

The future of wire insulation in vehicles looks promising. With continuous advancements in material science and technology, we can expect more robust and durable insulation solutions. These innovations will enhance vehicle safety and performance, ensuring smoother, safer rides.

How wiring works in modern vehicles is also evolving. Advanced insulation materials will support new technologies such as electric vehicles and autonomous driving systems. These rely heavily on reliable electrical networks, making high-quality wire insulation more critical than ever. Wire insulation is an integral part of a vehicle’s electrical system. It ensures safety, efficiency, and durability. By understanding vehicular wire insulation’s importance and staying updated with the latest innovations, you can ensure your ride remains smooth and safe. The small things make the biggest impact.